Digitally Transform Operations, Plant Maintenance, and Warehousing

Innovapptive’s integrated suite of connected worker apps empowers operations, maintenance, and warehouse teams to boost productivity, maximize uptime, and grow profitability.

We Bring Your Frontline Workforce,

Back-Office and Assets Together

We've partnered with some of the world's leading brands like AkzoNobel, Marathon and Newmont over the last decade to digitalize asset management, MRO spare parts and operations processes. With our help, these organizations are connecting frontline workers to back-office systems like never before.

20%

30%

60%

30%

Trusted By

Trusted By

Download Now

Our Solutions

Industrial process plants and manufacturing facilities using legacy systems confront daily operational problems, including:

- No real-time visibility

- Communication delays

- Misplaced or lost data

These organizations suffer:

- Limited Operational Flexibility and Agility

- Inefficient Data Capture, Storage, and Retrieval

- Slow Shift Handovers and Data Delivery

- Inadequate Safety Compliance and Audit Recovery

Innovapptive's mobile-first solution modernizes inspections, operator rounds, work instructions, fixed asset tracking, materials management.

- Digitized Task Planning and Remote Execution

- Manage Tasks, Crews, and Roles Anytime, Anywhere

- Real-Time Data Capture with Alert Creation

- Attach Documentation and Work Offline or Online

Asset-intensive organizations using reactive or run-to-fail maintenance strategies face:

- Lower frontline worker productivit

- Higher equipment downtime rates, and

- Greater risks for safety incidents

As a result, they:

- Limited Real-Time Process Visibility

- Data Silos and Work Order Backlogs

- Spare Parts Access and Decision Challenges

- Increased Maintenance Costs

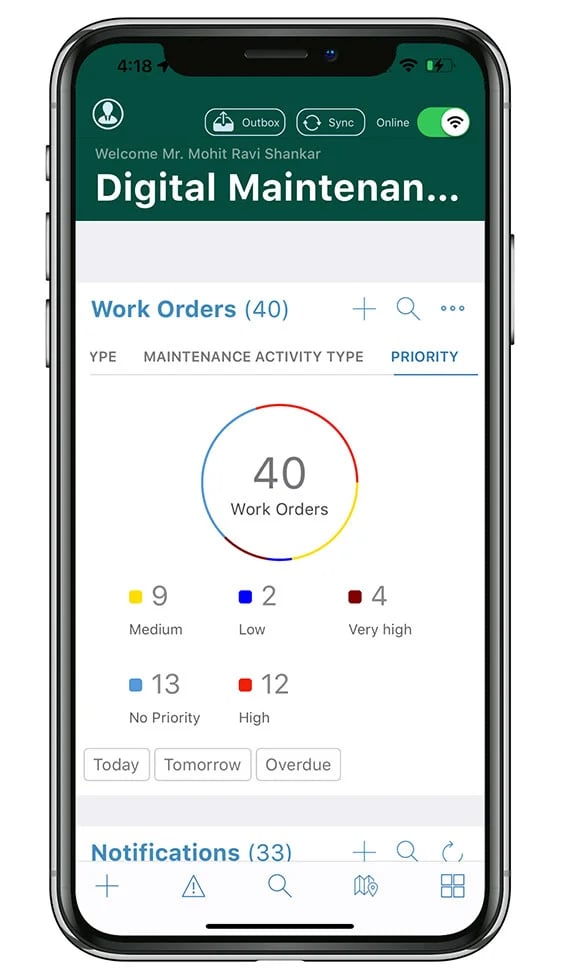

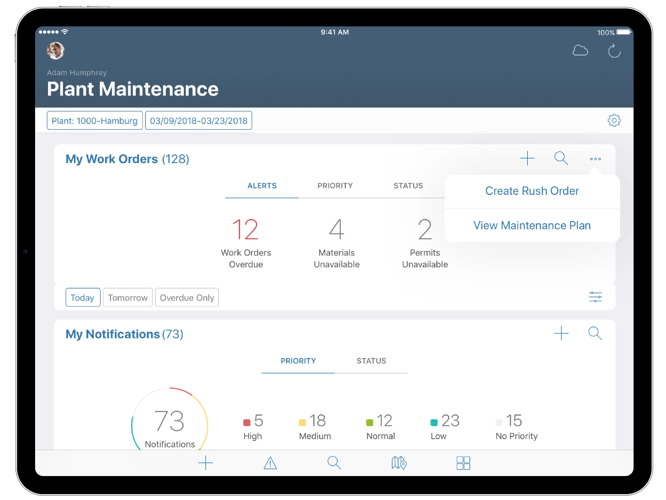

Innovapptive’s solution digitally transforms inspections, work instructions authoring, and spare parts and work order management.

- Create/Edit Work Orders and Notifications

- Assign Labor, Allocate Resources, Access Equipment History

- Remote Guidance, Multimedia Capture and Annotation

- Track Work Status and Location, Online/Offline Compatibility

Industrial warehouses using manual processes confront numerous pain points that prevent them from successfully accomplishing their goals.

- Poor inventory control and tracking

- Transaction processing errors

- Low or no-value inventory data

These manual processes and outdated technologies lead to:

- Limited Inventory Status Visibility, Low Worker Productivity

- Excessive Tasks, Wasted Time

- Delays in Movement and SAP Data Entry

- Lengthy Cycle Times, High Inventory Costs

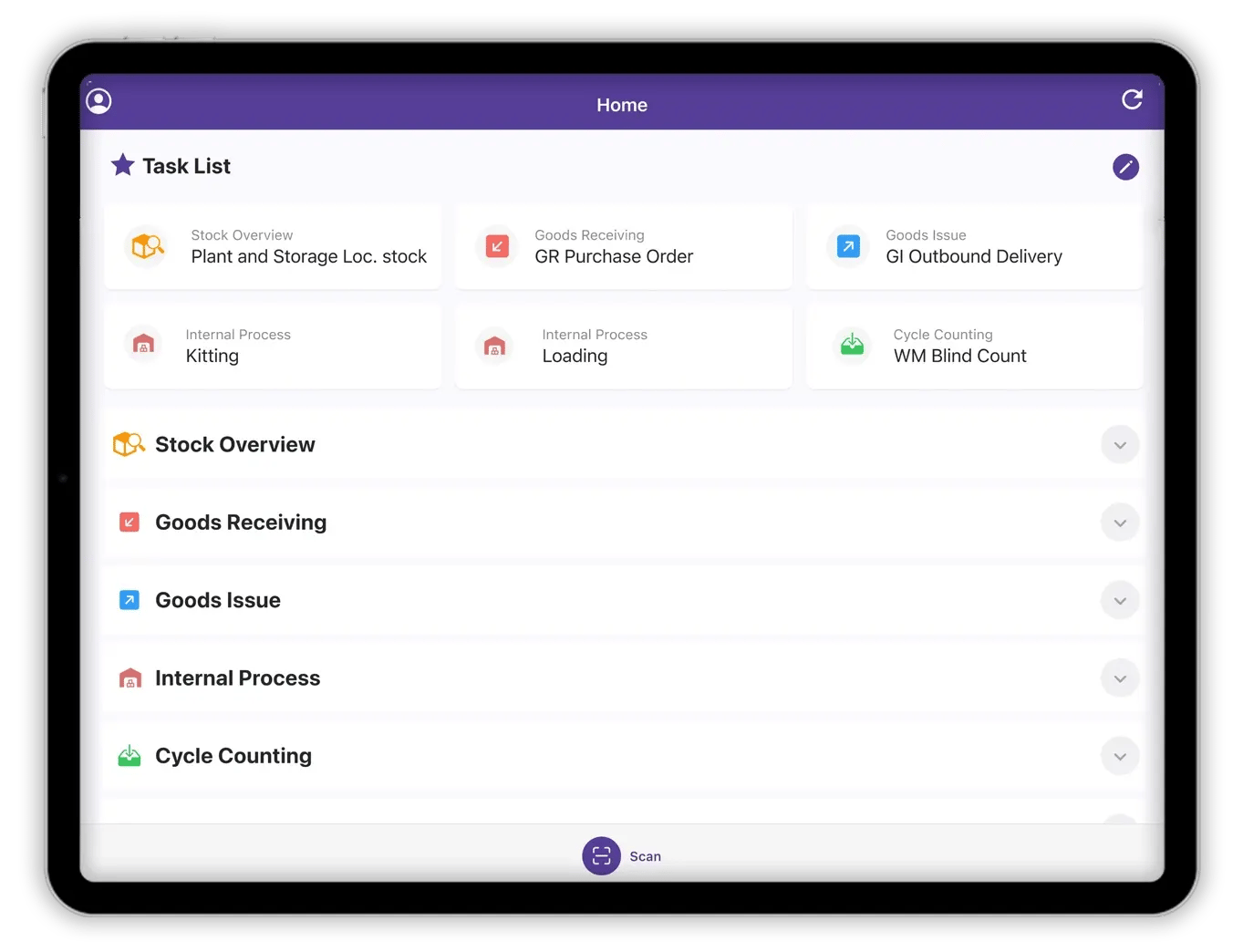

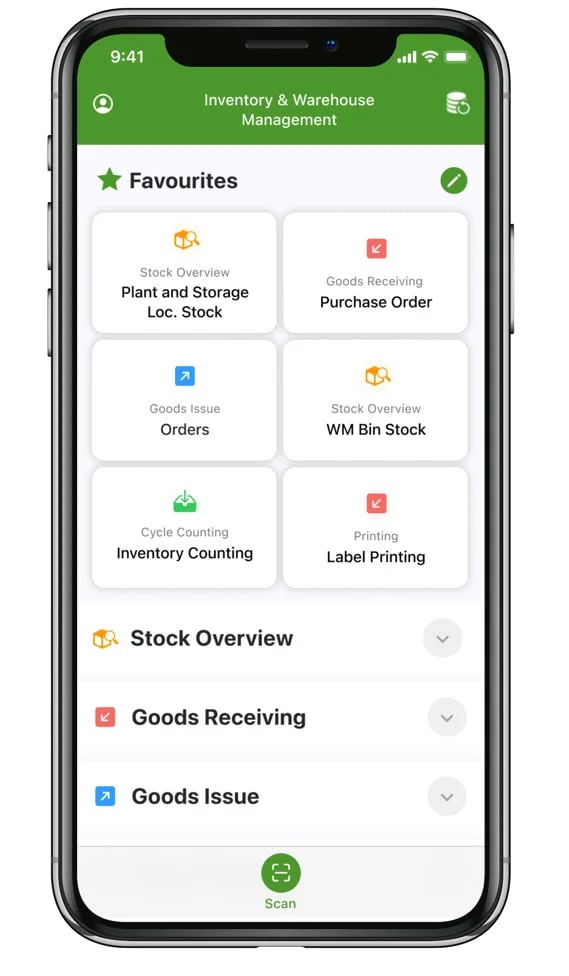

Innovapptive’s warehouse solution empowers digital inventory management, real-time transaction processing, and automated counts.

- Compatible with Rugged Scanners, Printers

- Check Material Availability, Location

- Manage Inventory, Issue Parts to Technicians

- Streamline Fulfillment, Functional Online/Offline

Our Solutions

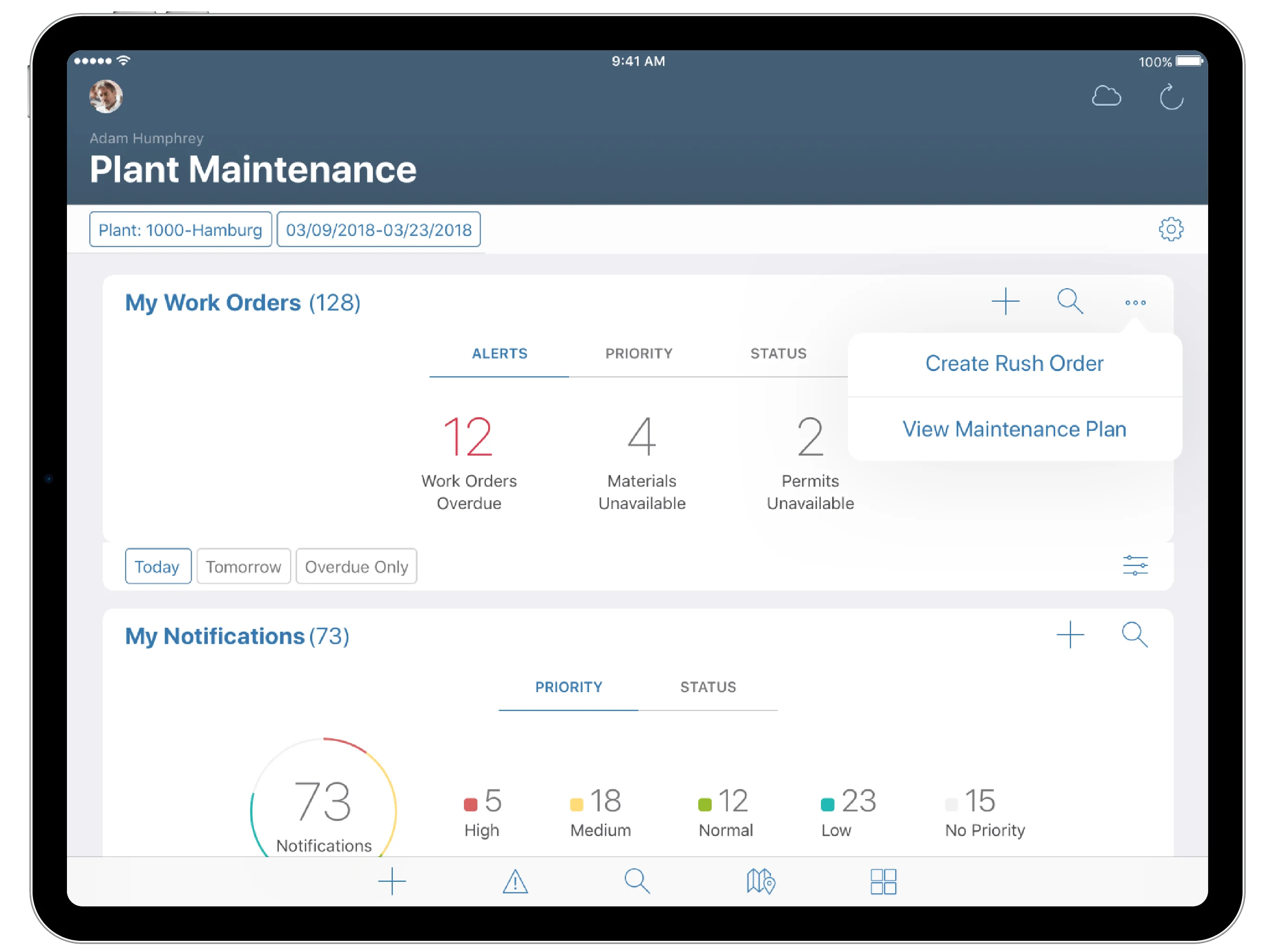

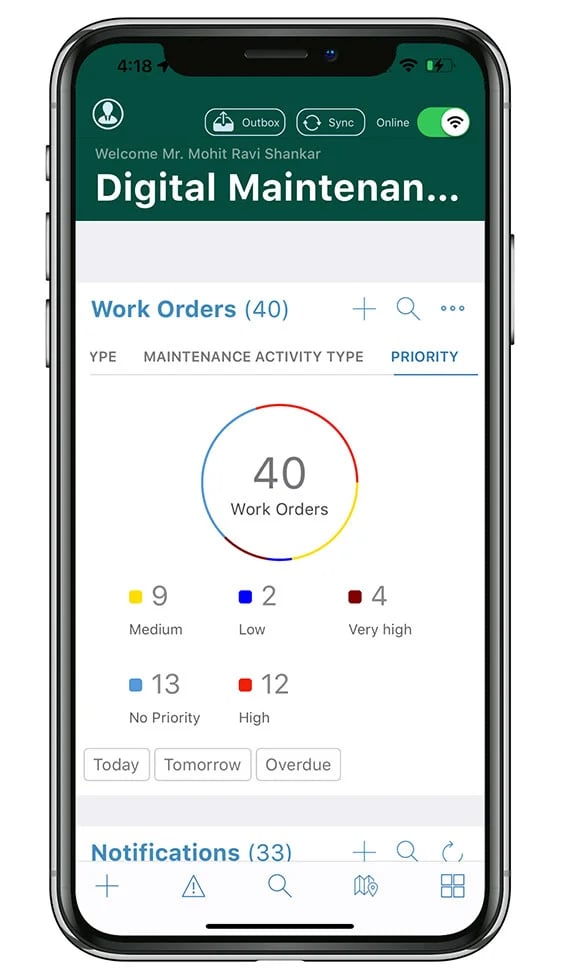

Maintenance

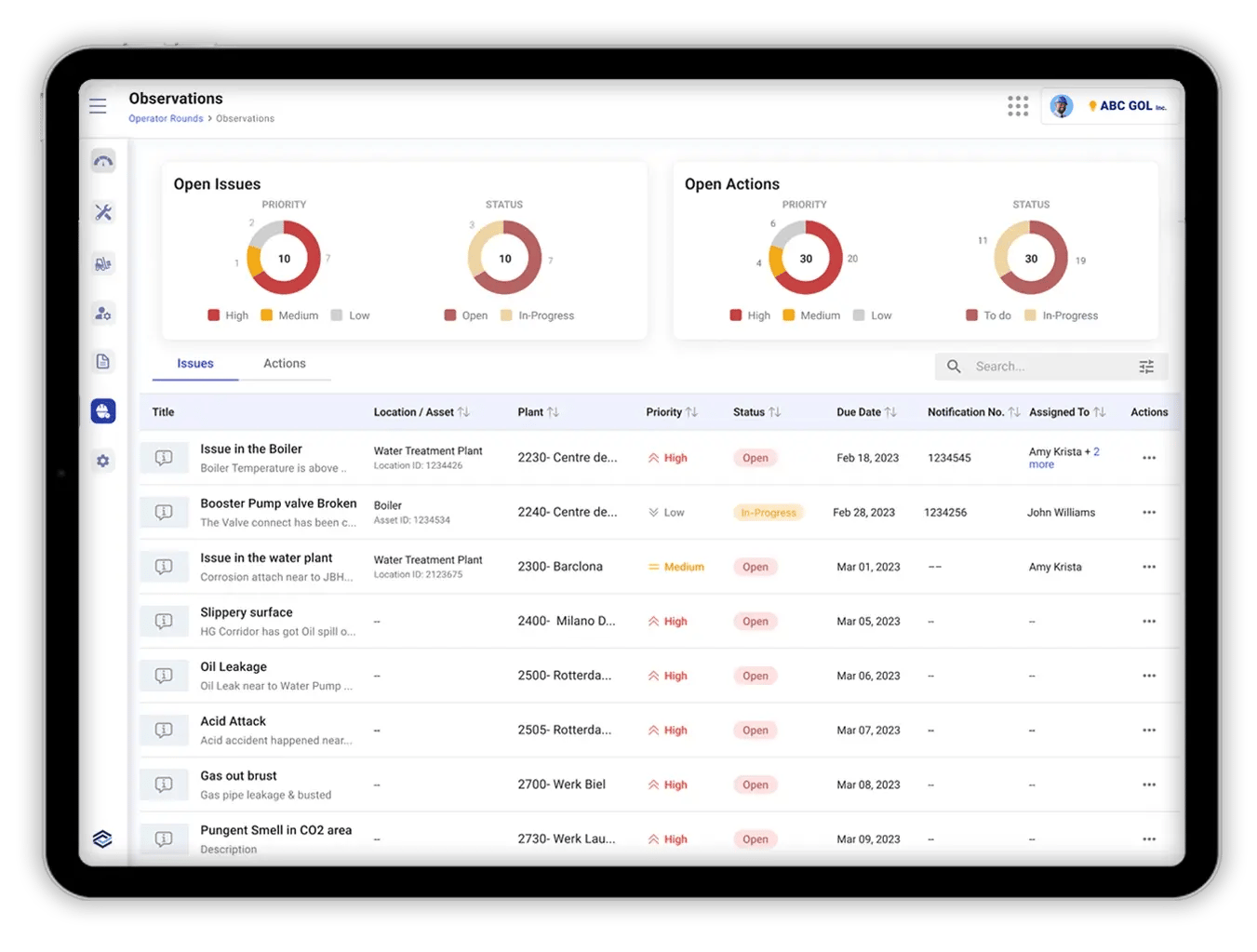

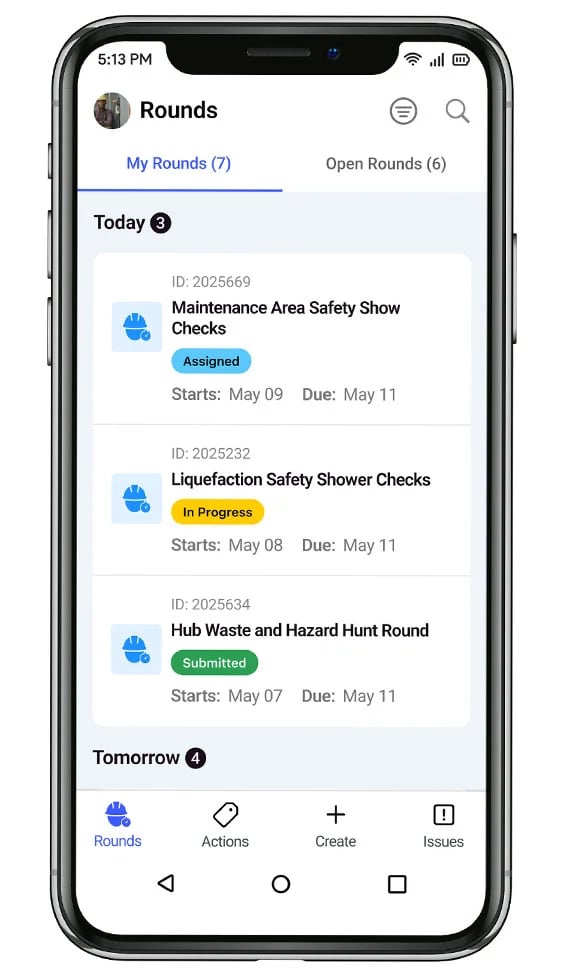

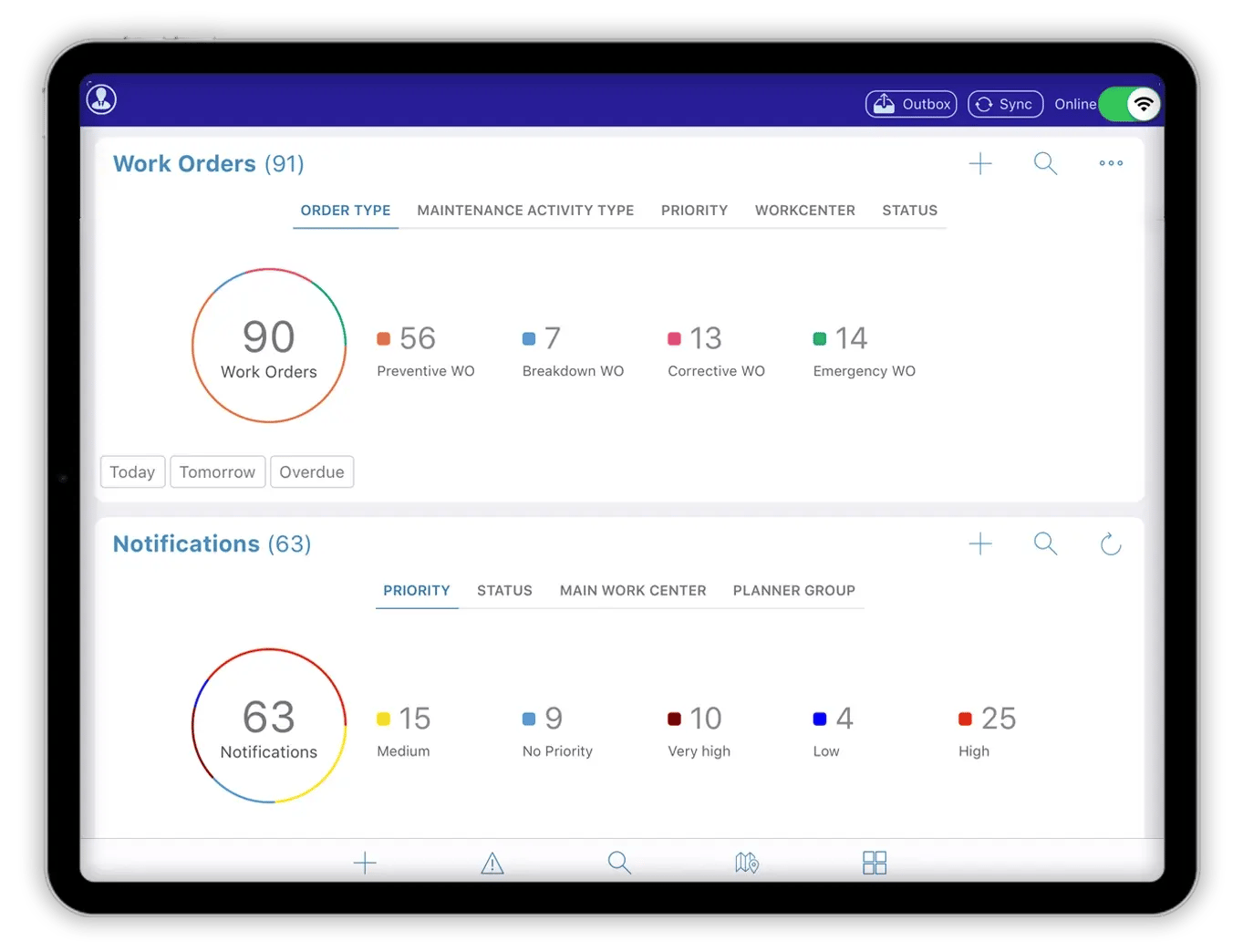

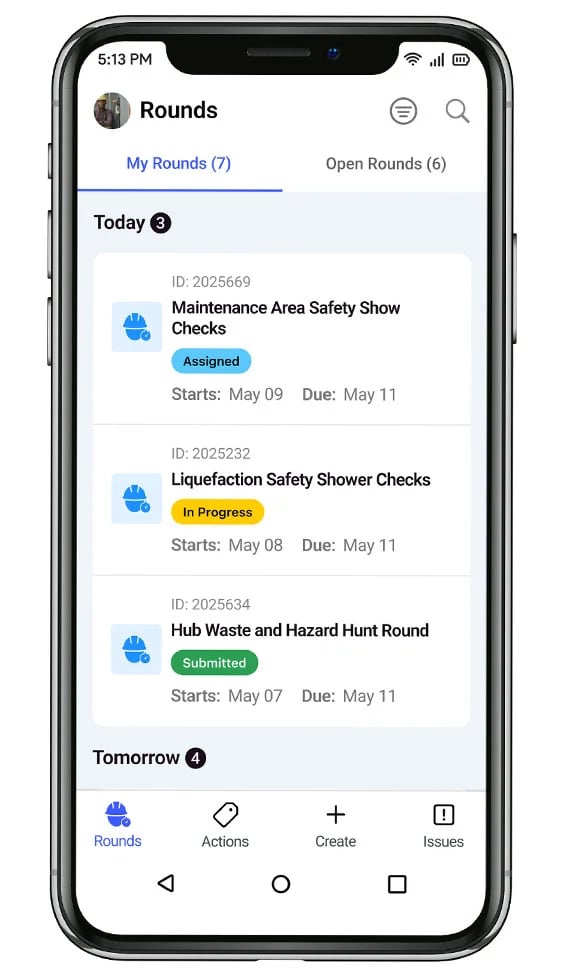

Innovapptive’s SAP-certified mobile work order and notification management applications support preventive and predictive maintenance strategies. Move away from an ineffective reactive, run-to-fail approach. Increase individual technician wrench time and improve overall productivity. Bring frontline workers, back-office systems and production assets together to seamlessly address plant maintenance, operations, and warehouse challenges.

Mobile and Desktop Capabilities

Perform vital data gathering and sharing on smartphones, tablets, and hands-free wearables - even in areas with poor connectivity. Our patented “low-code, no-code” platform and desktop control center dashboards empower users to create, schedule, execute, and follow up on mission-critical tasks, including:

- Inspections

- Work order management

- Work instructions authoring

- Spare parts management

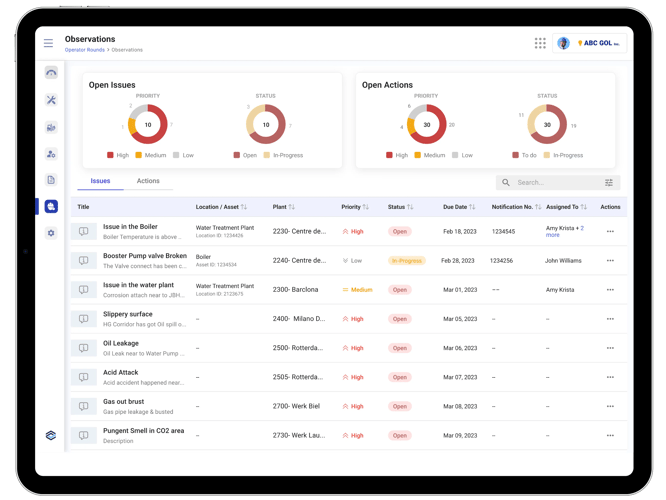

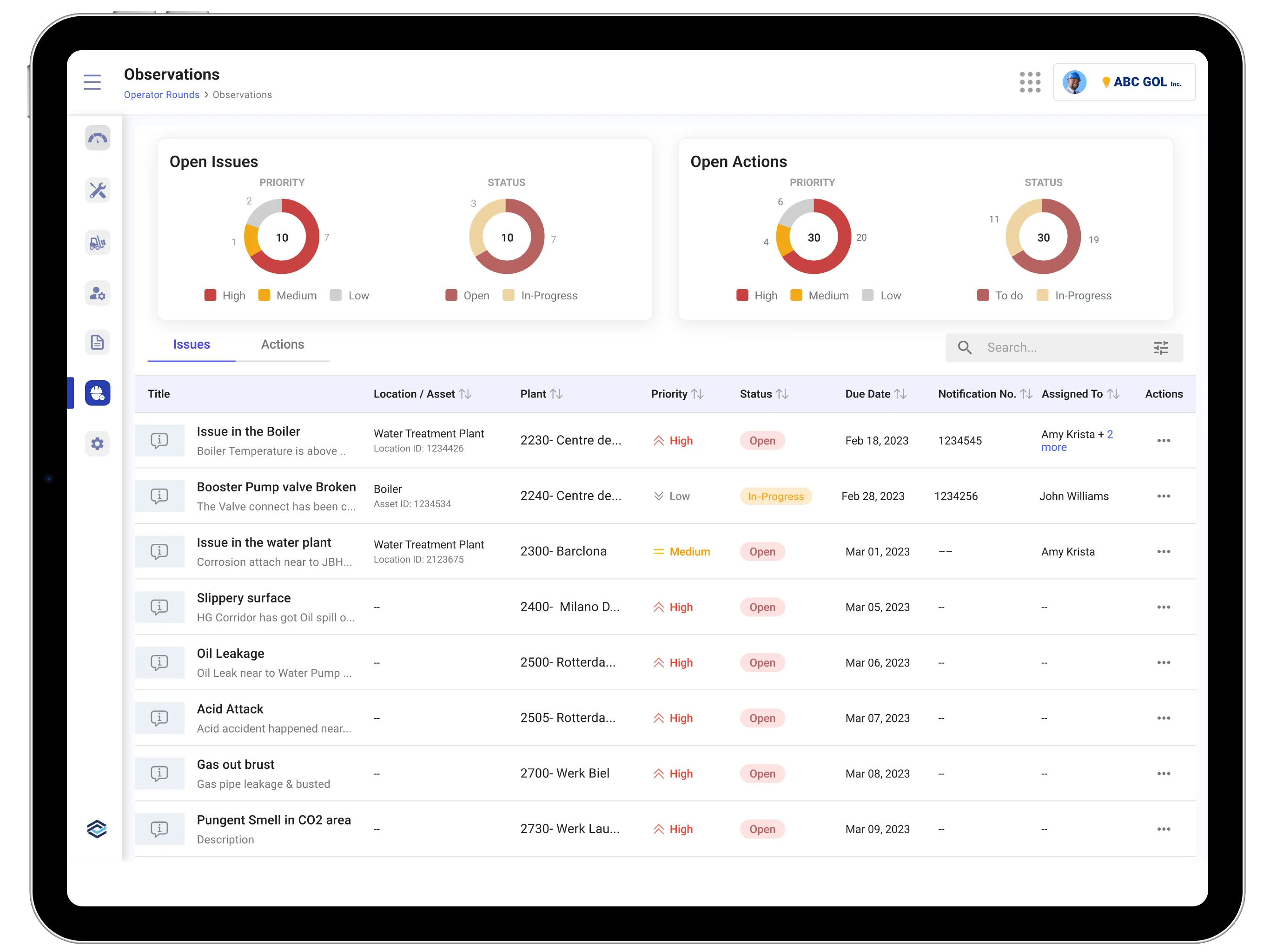

Operations

Innovapptive’s connected worker solutions eliminate slow, error-prone paper-based processes, enabling real-time operational information gathering and sharing. Our applications automatically upload data into the back-office ERP, delivering instant visibility that supports knowledge-based decision making. The result is a safer, more compliant plant that suffers less unscheduled downtime, fewer reworks, and smaller backlogs.

Mobile and Desktop Capabilities

Stay productive in the office or in the field - even when offline. Innovapptive’s solutions permit easy customization and configuration. Plan, author, schedule, issue, execute, and follow up on operational tasks. Analyze results in real time to determine appropriate actions:

- Inspections

- Operator rounds

- Work instructions

- Fixed asset tracking

- Materials management

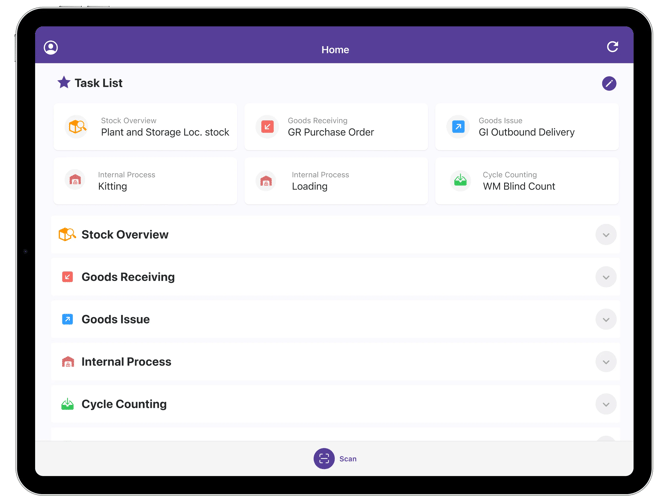

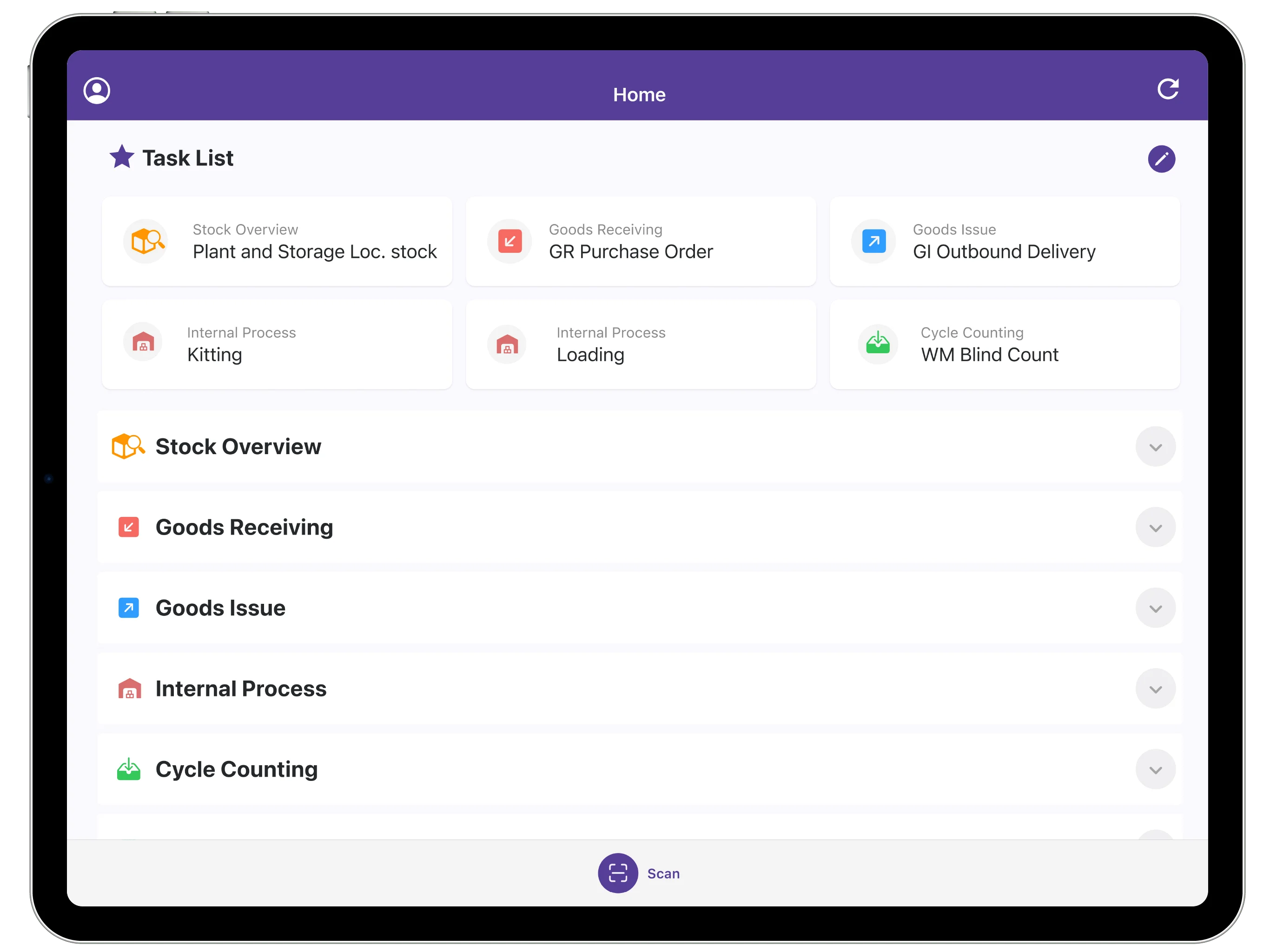

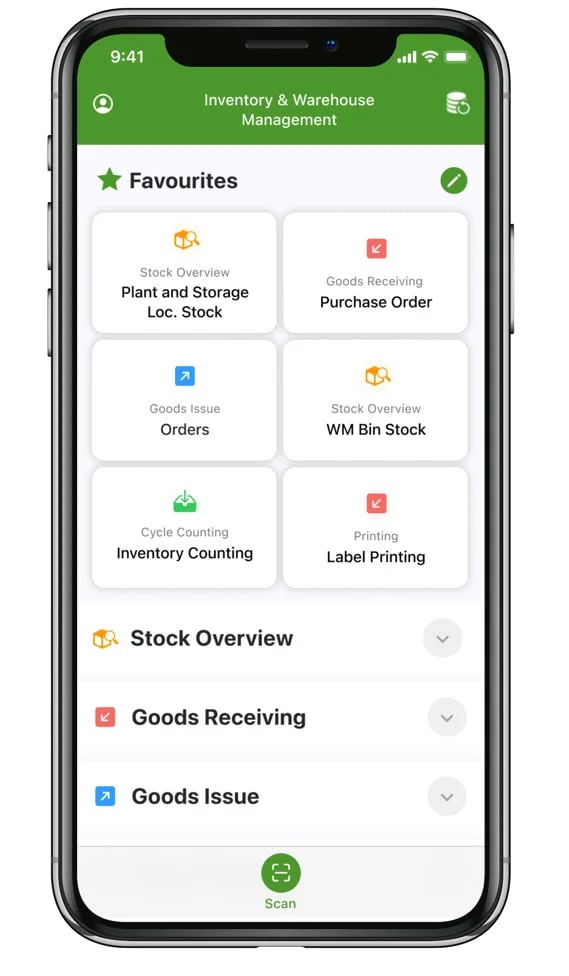

Warehousing

Innovapptive solutions provide real-time visibility and accuracy during every step of the warehouse or field storeroom process. Eliminate error-prone paper procedures and streamline workflows. Perform tasks using smartphones, tablets, scanners, mobile printers, and hands-free wearables - even when offline. Desktop applications and dashboards empower communication and collaboration between maintenance and the warehouse to reduce downtime.

Mobile and Desktop Capabilities

Innovapptive’s customizable, role-based solutions address manual data entry, transaction processing, tracking, low- or no-value data, throughput, cycle times, and other pain points. Use mobile applications and desktop control centers to:

- Manage inventory

- Automate counts

- Lookup materials, availability, and locations

- Conduct inbound, warehouse, and outbound transactions

- Transfer, reconcile, and control inventory

Our Solutions

Maintenance

Asset-intensive organizations using reactive or run-to-fail maintenance strategies face:

- Lower frontline worker productivity

- Higher equipment downtime rates, and

- Greater risks for safety incidents

As a result, they:

- Lack real-time visibility into processes

- Have information silos where key data gets stranded

- Suffer large work order backlogs

- Can’t get necessary spare parts when needed

- Have difficulty making knowledge-based decisions, and

- Ultimately pay more for maintenance

Innovapptive’s mobile-first maintenance solution digitally transform equipment inspections, work order management, work instructions authoring, and spare parts management.

- Create, customize, and edit work orders and push notifications

- Assign labor and allocate resources

- Access equipment details and maintenance history

- Issue and receive remote guided work instructions

- Capture and annotate images, videos, and PDFs

- Report and track work status, progress, and location

- Works in online or offline modes

Operations

Innovapptive’s connected worker solutions eliminate slow, error-prone paper-based processes, enabling real-time operational information gathering and sharing. Our applications automatically upload data into the back-office ERP, delivering instant visibility that supports knowledge-based decision making. The result is a safer, more compliant plant that suffers less unscheduled downtime, fewer reworks, and smaller backlogs.

Warehousing

Innovapptive solutions provide real-time visibility and accuracy during every step of the warehouse or field storeroom process. Eliminate error-prone paper procedures and streamline workflows. Perform tasks using smartphones, tablets, scanners, mobile printers, and hands-free wearables - even when offline. Desktop applications and dashboards empower communication and collaboration between maintenance and the warehouse to reduce downtime.

Tailored For Asset-Intensive Industries

Oil & Gas

Chemicals

Boost safety and regulatory compliance while monitoring asset health in real time.

Mining

Spot areas of concern regarding equipment condition or safety and take prompt remedial action.

Manufacturing

Gain real-time visibility into current operating conditions to make better decisions for faster responses.

Utilities

Reduce equipment downtime incidents, improve asset reliability, and promote a safer workplace.

Since the start of the project we have been nothing but pleased with the quality of the service we've received from Innovapptive. The whole team from the sales team to the project team have been nothing but supportive

I'd say Innovapptive for us has been a reliable product. It was easy to implement, the service has been good. So I would recommend checking them out if you're looking for some help with your workflow.

Innovapptive mobile solutions. It's Great. It's a one-stop shop for all the engineering activities and administrative duties basically. It allows us to keep everything current and up to date.